Irrigation Technologies

Our project has piloted a number of new approaches to irrigation and horticulture practice that are based on farmers' site-specific barriers and issues. A key aspect of this work has been ensuring that womens' concerns and challenges are specifically addressed, since in many cases the work of growing vegetables falls to the women in a given household.

Rock head tank

Micro basins

Multiple-head sprinkler

Raised Furrow-Basins

Irrigation for waterlogged areas

Raised furrow-basins are flat beds that are surrounded by bunds, with drainage canals on the edges. Inside each basin, raised beds and furrows are made for vegetables. These beds can be flattened into basins during rainy seasons for rice production. Raising the beds between canals allows a deeper root area in case of rain, but efficient use of water during irrigation.

Sites Using This Technology

Aloet

Benefits

Adequate drainage in waterlogged areas for a number of vegetable crops, including onion, cabbage, carrot, and cowpea

Ease of irrigating compared to flooding and watering cans

Lower cost than pressurized systems

Allows use of waterlogged areas throughout the year

Challenges

Erosion by rain and irrigation water, requiring ongoing re-shaping of beds and clearing of furrows

Higher up-front labor cost than many other irrigation approaches

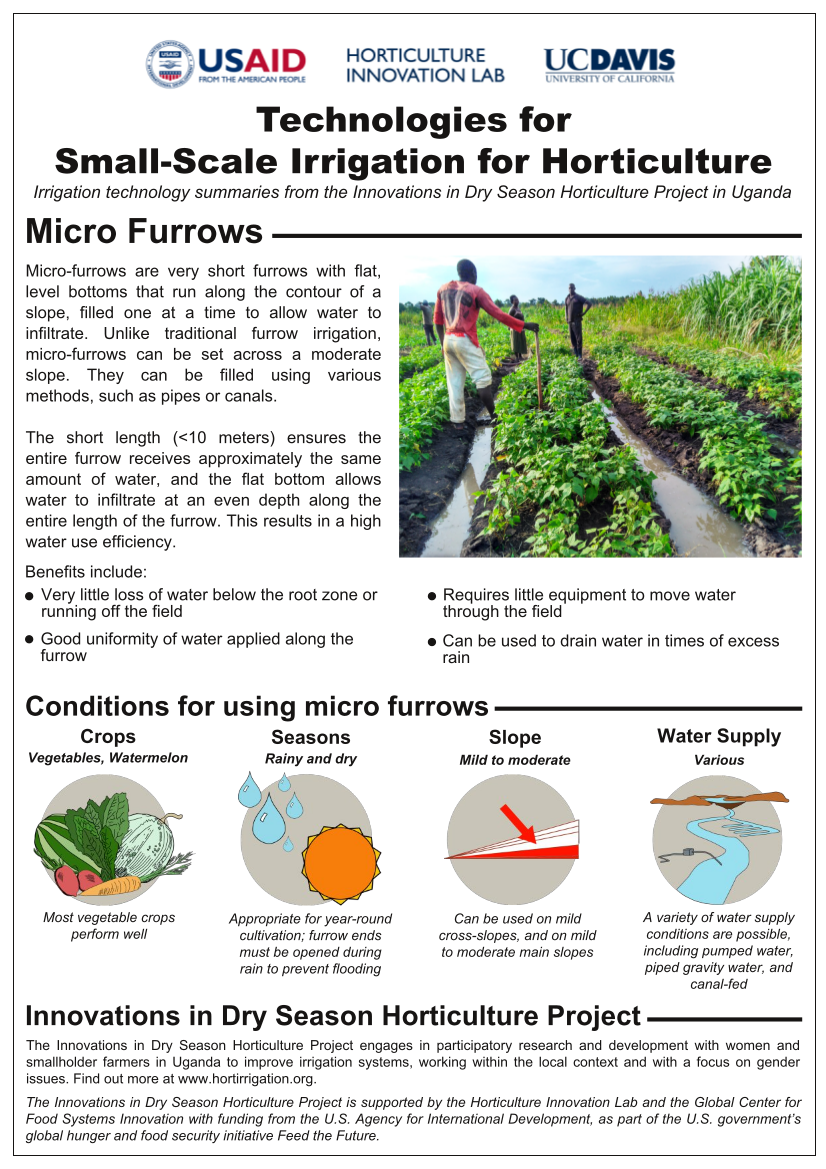

Micro Furrows

Furrow irrigation for moderate slopes

Micro-furrows are very short furrows with flat, level bottoms that run along the contour of a slope, filled one at a time to allow water to infiltrate. Unlike traditional furrow irrigation, micro-furrows can be set across a moderate slope. Each furrow can be filled by an open pipe, either from a pump or gravity system.

Sites Using This Technology

Kabos, Kyekidde

Benefits

Water reaches the end of each furrow quickly and infiltrates evenly, with good uniformity along the length

High water use efficiency: no tail water exits the furrow at the end, and small surface area limits evaporation

Deep infiltration allows for longer time between irrigation applications

Can be used with various water systems: channels, piped water, or jerricans

Challenges

Furrows must be cleared regularly to maintain level bottoms

Furrows and tops of beds must be flattened well

Moderate labor required to fill each furrow

Raised and Terraced Main Canals

Easy control of furrow irrigation in canal-fed systems

A main canal for feeding water into irrigation furrows, which is raised above the level of the field to allow easier control of water into furrows. The canal is terraced to have a minimal slope in each section of the canal. This is done to ensure an even distribution of water through discharge points in along the canal. Spiles are inserted into the sides of the canal to discharge water to the plot.

Sites Using This Technology

Aloet

Benefits

Easy control of water into furrows

No moving of soil which can damage furrows and canals

Good uniformity of flow into each furrow

Little labor required in irrigation

Can be used in areas with highly erodible soils

Challenges

High labor requirement in making raised main canal

Need for regular maintenance in cleaning and re-terracing canal

Micro Basins

IMPROVED INFILTRATION FOR LARGE WATER APPLICATIONS

Small sections of land boxed in with small bunds and leveled to be flat. Water is applied into the basin using a pipe, canal, or jerican, filled to the top of the bund. The water is held inside and infiltrates down into the soil profile. This allows very high application rates, as it prevents runoff. This helps farmers irrigate deeper and crops to have a larger store of water before irrigation is needed again.

Sites Using the technology

Atari, Kabos, Tente

Benefits

Long interval between irrigations

Adaptable to many water supply systems

Allows farmers to use very high flow rates

Challenges

Requires large amount of labor for land leveling and bund making

Encourages disease in crops susceptible to fungal infection, such as tomato and onion

Manual Pivot Piping System

Minimal pipe length for maximum irrigable area

A system of piping that lays a buried section to the center of the field to be irrigated, and attaches a raised pipe (HDPE or Layflat) that can rotate in a circle. This mimics the layout of a traditional center-pivot system, but is manually moved to the plot a farmer desires to irrigate.

Sites Using This Technology

Kyekidde, Atari

Benefits

Lowest cost of pipe for the area covered by the system

Allows small, individual plots to be irrigated separately

Simple installation and use

Minimum cost of fittings and installation

Challenges

Requires multiple people to move pipe from one plot to another

Can damage standing crops if care is not taken when moving pipe

Does not minimize pressure losses in pipe--requires some excess pressure capacity at pump

Our Work

Direct-fill Furrow System

In areas where the water source is below the field, a pump is necessary. Once farmers are using a pump, it is often possible to use a flexible pipe to deliver the water directly into furrows. This can be an efficient way of irrigating, since there is almost no loss on the way to the field and almost all the water ends up in the root zone.

Sites Using This Technology

Atari, Kyekidde

Benefits

Can be used in sloped areas where surface canals will not function

Does not require technical know-how nor precise leveling of canals

Eliminates water loss through seepage and evaporation

Challenges

Requires a flexible pipe, which is more expensive than canals

Constant movement of the flexible pipe causes wear and tear

Pipes can be accidentally dragged over crops, causing damage

Water-filled pipes are heavy, making it difficult for some users (especially women) to operate

Our Work

Tied Furrows

Achieving uniform infiltration in sloped furrows

In closed furrows, water accumulates at the end if there is even a small slope, so it can be difficult to get very good uniformity of water from the start to the end of the furrow. A "tie" is a half-blockage inside a furrow, which is used to slow down the flow of water to achieve more even infiltration before and after the tie. This approach is used in closed furrows when it is difficult to get a level enough furrow to ensure even infiltration along its length.

Sites Using This Technology

Kyekidde

Benefits

Can enable use of furrows on sloping land

Improves uniformity of water infiltration along a closed furrow

Implementation is simple, low-cost and requires little labor

Challenges

Only applicable in closed furrows with cut-back irrigation--would be less efficient than normal flow-through furrow irrigation

Ties must be removed in rainy seasons to prevent waterlogging in the field

Our Work

Water-powered Pump

No cost, low volume, 24 hour pumping

A water-powered pump uses the force of the current in a stream to turn a wheel, which generates pressure to pump water upslope. It is installed inside a stream or river, and is connected to a delivery pipe to take water to a nearby plot. This system produces a low pressure and flow, so it is suitable for relatively nearby gardens that are not elevated high above the stream-- less than 6 meters vertical head and less than 100 meters lateral distance. The pump continues all the time, so some water storage at the plot is necessary in addition to a method for distributing water. Distribution can be done with watering cans, drip systems, or any other low-pressure method.

Sites Using This Technology

Tente

Benefits

No cost of pumping

24-hour pumping

Challenges

Difficult to install in stream

Low head and flow rate

Need for water storage at the field (e.g. water tank)

Twigs and other debris in the stream often clog the wheel, impairing its function.

Our Work

Ox-powered Reservoir Construction

Method of digging a water reservoir using animal traction

Sites Using This Technology

Tente

Benefits

Low cost of excavation

Easy to use and learn

Challenges

Can only be made in periods with some rain and soil moisture

Sealing can be costly in areas with porous subsoil

Requires well-trained oxen that do not scare easily

High physical strain of labor

Our Work

Animal Traction Leveling

low cost land leveling with animal traction

A method of leveling fields for furrow irrigation that requires only oxen and a tool for scraping and depositing soil. This greatly reduces the amount of labor required for leveling. Three people are needed to level: the navigator who shows the oxen operators where to cut and fill, the ox-driver who directs the oxen, and the machine operator who handles the scraper. The team moves in roughly circular motion around the field, cutting raised parts and filling depressions until the field is roughly flat. Final finishing can be done by hand-hoe.

Sites Using This Technology

Aloet, Atari

Benefits

Much lower labor requirement for land leveling

Easy to use and learn

Challenges

Only applicable in mid-size plots, approximately one-quarter to one acre

Appropriate for mild slopes, less than 4-5%

Can only be made in periods with some rain and soil moisture

Requires well-trained oxen that do not scare easily